IN Platform

Towards the ideal process

Have you imaged how your organization production process could be if every operator, machine and device would have access to their own assistant to solve the routine tasks related to sharing information?

-

In this way the operators could invest their efforts to solve the challenges that every process bring along instead using their valuable time to register manual data.

-

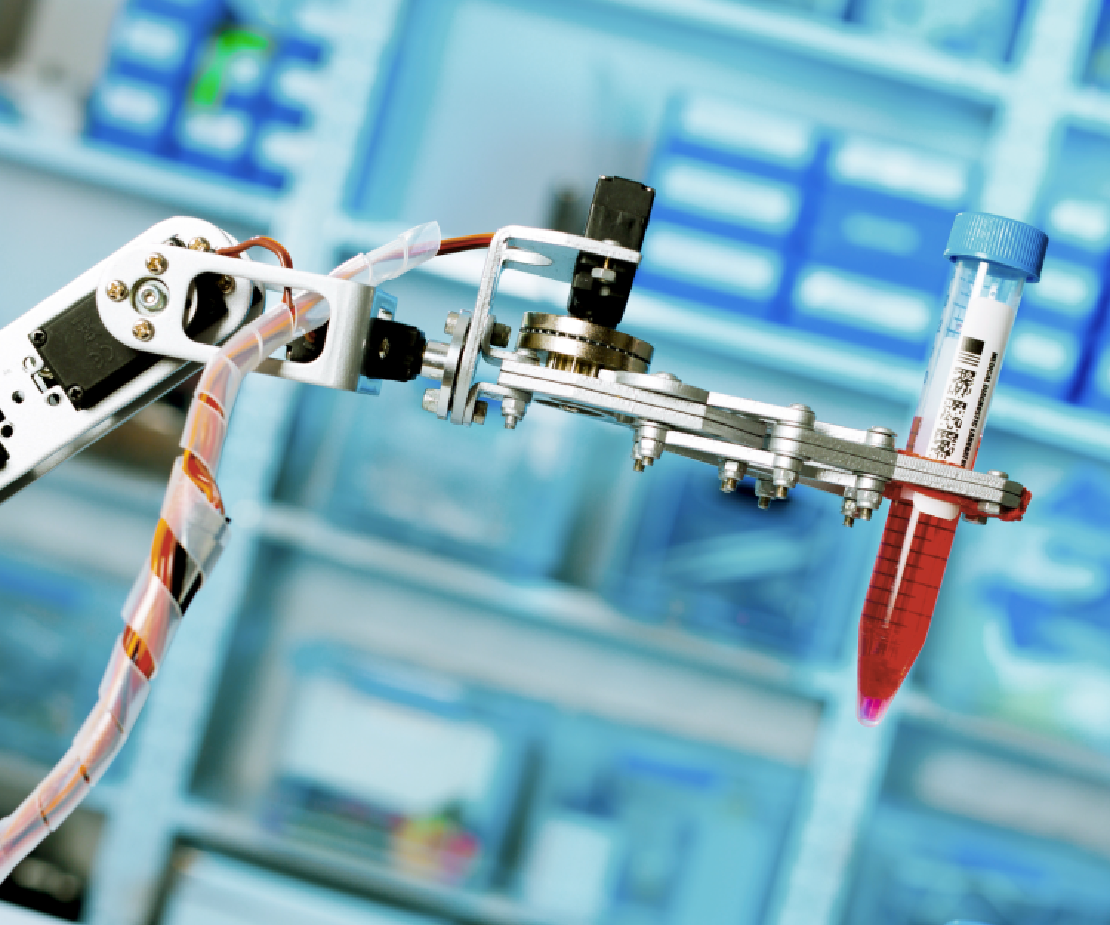

Your machines - no matter their original restrictions, technology and manufacturers - can be integrated to the process adjusting themselves to its evolution and sharing real time indicators and deploying signal alarms when necessary.

-

And your devices - among temperature, humidity, air quality, pH sensors, weight scales, and even external data sources like meteorological data - can provide real time data needed by operators and machines.

Ant the end of every production shift the results would have, among others, the following benefits:

-

The persons involved would have taken decisions based on truthful and timely information.

-

The real time supervision would have allowed to adjust the process according to its evolution and would have deployed opportune alarms.

-

The information about the process would be filed with the purpose to provide traceability.

-

Your team would have available reliable data sources to analyze the performance and identify improvement opportunities.

How do we achieve it?

The architecture of the Platform IN from VIDAL & ASTUDILLO is based on micro-services (which we call workers) are in charge of solving specific routine tasks and communicate in a particular fashion.

In a sense they are similar to human operators following their functions manual to realize routine activities, having the advantage that their results are predictable, don’t get fatigued, and being available permanently.

They can also be integrated while the process evolves, assuming only specific support tasks to prevent the eventual traumatism associated with the implementation of traditional software.

Moreover, the Platform IN from VIDAL & ASTUDILLO offers clear advantages over the traditional alternatives of control production systems and enterprise resource planning systems, like SAP and other ERP:

-

They can be adjusted specifically to the needs of every customer.

-

They can be deployed in commodity hardware (economical and easy to source).

-

They can be deployed in redundant arrays, to increase throughput or replace failing workers.

-

They implement identification and encrypted messages between the data sources and those who consume them.

-

They offer simplicity to diagnose them, which minimizes the eventual need for specialized personnel in-situ to resolve eventual problems.

-

They can interact virtually with any kind of hardware and software.

What are examples about its application?

Among the real cases of implementation of the IN Platform there are the following:

Supervision of critic chilling process

Purpose: A particular point on the process should achieve certain parameters that depend of critical infrastructure.

-

Several workers are in charge of taking and publishing precise data from the temperature sensors on the machinery and operations rooms, and another functioning parameters of the equipment, pumps, and compressors. The instruments involved are sourced by different manufacturer with different communications protocols.

-

Redundant workers are in charge of analyzing the received information to determine if they have to deploy audible and visual alarms in certain places of the plant, and even send messages via applications like Telegram to the involved personnel to notify them about the events.

-

A particular worker is in charge of filing the information about the operation on a data base to ensure the product traceability.

-

Another worker publishes the information to a Graph data base to allow the process analysts to identify data correlations and anticipate process failures.

Incubation Plant

Purpose: To achieve the highest hatching rate in a poultry incubator plant.

-

A worker is in charge to monitor setters and hatchers registering their key operating parameters, temperatures, humidity, CO2 levels, sound levels to determine the hatching curves and operator’s interactions with the machines.

-

Another worker is in charge of monitoring the temperature and humidity of the incubation rooms.

-

Another worker is in charge to synchronize the inventory from the planning production platform with the information on each machine, to allow operators to charge and discharge the machines using their interfaces.

-

Another worker is in charge of monitoring the operating parameters to evaluate possible alarms and even predict them to inform the involved personnel.

-

A worker receives and stores the information from mobile applications used by the quality control personnel in process like ovoscopy.

-

Another worker publishes the data in a Graph database to be used by a veterinary to allow them identify factors that affect the hatching results, that may include data related to the lots, like age of the chickens, duration in cold storage, clients, effects of the environment and other machine operation information.

-

Another worker is in charge to file all the published information provided by other workers in order to keep a complete traceability registry required by sanitary authorities and clients.

Product dispatch

Purpose: Simultaneously evaluate the conditions of a past product delivery, that the vehicle is in conditions to be loaded and formalize the product dispatch.

-

As soon as a vehicle reach the dispatch platform , a worker is in charge of directly retrieving the data from the temperature sensors of the container from both, the current conditions and the historic ones related to the last delivery.

-

A worker is in charge of providing the ERP software with the data of the identified baskets/pallets via RFiD to prepare the delivery document.

-

Another worker is in charge of using the information provided by the other workers to present both the vehicle driver and the dispatcher operator with information to evaluate that the required conditions of the transport are adequate, and the data used to formalize a new dispatch.

Your particular case

Each process and requirements are particular. Surely we will find diverse alternatives to help you reach your objectives.

Get in touch with us and let’s talk about how your process can take advantage of the benefits provided by our platform.

Related Posts

Integration

Whatever the activity of your organization, you will have noticed that each phase of the production process generates a great amount of information originated by the personnel or by the machines, sensors or devices that intervene in the process.

Read more

Machines and equipment

In your industry your competition has the same access as you to the same type of machines, it is only a question of resources.

Read more